We never stop talking about movements, their balances, barrels, bridges, gear trains and so forth, rarely giving more than a fleeting description of the dial. But what is the first thing the customer sees when peering through the shop window at a new watch? Its face.

Faces

The fabrication of a watch dial involves a multitude of crafts, from printing to guilloché, from stone setting to applying SuperLuminova. These skills are extremely specialised and demand the greatest expertise and the steadiest of hands. You just have to take this issue of Europa Star and flick through it to see the complexity of some of the watch dials on the market today. My research took me to Stern Creations, the dial entity behind the Richemont Group and to Cadran’or, an independent dial manufacturer tucked away in the Jura mountains.

Base plate

The beginning of a dial’s life

All dials start their life on a drawing board or on a computer and are often accompanied by a number of constraints before the designer has even put pen to paper or mouse to screen. The main restrictions come from the type of movement, which greatly influences the design of the dial. For example, a big date will need a big aperture, a chronograph will need counters and a moon phase indication will need a moon. But, it’s not only the functions that limit the designer, the thickness of the movement can also limit the depth of the dial and openings in the dial will be determined by the position of the components in the calibre. So the watch designer has to follow the architecture of the movement, but this is only the beginning of the challenge as he or she will also need to make the dial easy to read, convey all the design codes of the brand and create something totally unique and beautiful – it’s no easy task.

Once the design has been agreed upon, the dial maker will begin with a plate of metal called an ébauche, usually in silver, gold or nickel. Once the ébauche has been cut to the correct shape, two small feet are riveted to the backside of the plate. These two feet are like two little metal sticks, about 1 to 2 mm in length, on the backside of the dial that will rest on the movement once the watch is encased. If the dial is in gold, the feet are always in gold, however if the dial is in nickel, the feet will be in copper. If one of them breaks, the dial is useless so they have a very important role and each one is tested for strength. The next step is the creation of the apertures with a column press machine that pushes down on the dial much like a giant paper hole puncher. Next the dials are hardened to between 90 to 120 Vickers for strength. They are then cleaned and polished and are ready to start their journey to be decorated.

Different techniques

There are a variety of different techniques in the art of dial making, some of which haven’t changed for centuries, others that have just been invented. Here is a selection of some of the main techniques that are being used in today’s haute horlogerie timepieces. Please note that for confidentiality reasons, the dial manufacturers prefer not to publicize the brands for whom they work. The photographs in this article are current illustrations of the different techniques used and are not linked with the dial manufacturers mentioned in this article.

Tapisserie

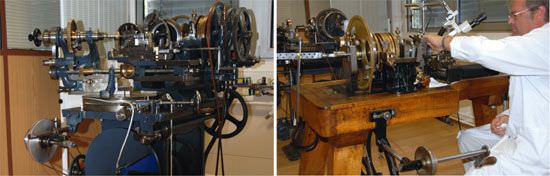

One of the oldest forms of dial making is tapisserie. The technique involves a plate (about the size of a small tea saucer), which is engraved with the design of the dial. This plate is then placed in a machine that mechanically reads and copies the design onto the surface of the dial. These aren’t CNC machines either, they date back to the last century, if not before. Stern Creations, which was founded way back in 1898, has an incredible selection of ebony plates that are from the days of the pocket watch with designs of cherubs playing the lyre and couples galloping on horseback. In this fascinating workshop, things haven’t changed much. Only the ebony plates have been replaced by metal ones and there is electricity instead of candles!

Tapisserie machine at Stern Creations

Méga tapisserie motif on Audemars Piguet’s Royal Oak Offshore Singapore

CLASSIQUE COLLECTION by Breguet showing hand guilloché

Guilloché main / hand guilloché

When we think of hand guillochÉ, we often think of one or two styles, Breguet perhaps comes to mind, but there are hundreds of ways to guilloché a dial. Hand guilloché is the creation of straight or circular patterns on the dial by engraving with a machine. These lines catch and reflect the light in such a way to give movement to the dial. Again, these machines are often antiques, with the oldest machine at Stern Creations dating from 1868. The metal from the dial is carved away by expert hands that need years of experience as the pressure and the speed of the miniscule chisels must be perfect and continuous for a faultless result. In fact, there are only a handful of craftsmen who know the art of hand guilloché. The same effect can be achieved using CNC machines with their diamond tipped tools, however, to the trained eye the result is not the same. Hand guilloché leaves an elegant, thinning of the line as the artist comes to the end of a stroke, it is gradual, unlike a CNC finish which is 100 per cent precise. Neither technique is better than the other, they are just different.

Guilloché machines at Stern Creations

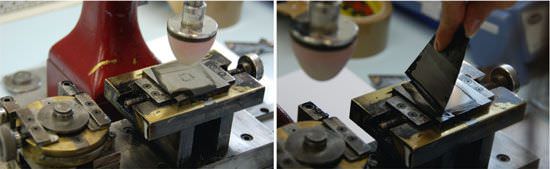

Décalquage / dial printing

Have you ever looked at a dial and wondered how the numerals are painted on so perfectly? The technique is very impressive, and again, is achieved by a method that hasn’t changed for centuries. The process starts with a plate with the numerals, railway tracks, logo etc. that are engraved into the metal by means of a chemical process (in the past they would have been engraved by hand). The plate is spread with ink and cleaned so only the ink in the design is left. A silicon or gelatine head then stamps down on the plate and picks up the ink and it is transferred to the dial. Watching the process, on these old machines with ink everywhere, you wonder how it is possible for the numerals to be transferred to the dial without a smudge, but it works and the result is immaculate.

Dial printing at Stern Creations

Truly precious

You surely remember Tissot’s rock watch and the one they made out of wood from the 1980s. Well, unusual materials have become increasingly popular these last few years. Brands such as Rolex, Piaget and Jean Dunand have been working with some very exotic materials. Precious stones such as 40 million year old petrified coral, meteorite, Dalmatian jasper, lapis lazuli, onyx, turquoise, malachite, tiger’s eye, platinum ore, abalone shell and rare opals add an eye-catching backdrop to a watch’s dial. Exotic stones present many challenges for the dial maker due to the stones’ fragility. The stones are highly polished before having their apertures cut out. The apertures cannot be created so easily. At Stern, they have tried many methods, but have found that cutting by ultrasound is by far the most efficient. The stones are then attached to an Ébauche for stability.

Jean Dunand Orbital Tourbillon Pietersite dial

Mother-of-pearl dials

Dial colouring

Achieving the perfect colour for a dial is also an art in itself. The two main techniques are metal plating and a version of four-colour printing. Many different colours can be achieved by plating, whether it’s yellow, rose or coloured golds, rhodium or silver to name a few. The problem is that the Ébauches have to be dipped into chemical baths for precise periods of time. Timing is everything as one second too much and the colour will be different from the series before. Four-colour printing is similar to the process used for printing newspapers and magazines. It is often used when different colours or varying tones of colour are required on the same dial.

MONACO CHRONO GULF by TAG Heuer

Difficulties

There are many difficulties surrounding the art of dial making. One tiny, minute scratch or spec of dust under the Zapon (final finish which is like a varnish that protects the dial from oxidization) sends a dial directly to the bin. A case maker can recycle gold and start again, but not dial manufacturers, they have to start over.

Another problem is that dials are extremely fragile. Sometimes several dials will need to be made to be sure to have one good one. These are calculations that are worked into the price, but it shows how difficult some of the dials can be and explains why some dials can increase the price of a timepiece considerably.

Gem setting and quality control at Cadran’or

Switzerland versus Asia – the pros and cons

Switzerland isn’t the only country producing dials. Asia has become experienced in making dials for quite a while now, and the quality is excellent. However, Switzerland has a huge advantage when it comes to innovation as Daniel Brogile, Director from Cadran’or explains, “The difference between Switzerland and Asia is in the difficulty of a project. There are certain things that Asia can’t do. Throughout the Jura and La Chaux-de-Fonds are a network of artisans, from lazer cutters to those who can cut with high pressure jets. We find everything we need. In Asia, if they can’t do it internally, they just can’t do it.” What often happens is that an individual, such as a gem setter for example, will be very successful inside a company and then decide to continue working for the company, but on an independent basis so he or she can accept other clients too. This has led to a huge network of independent artists working in the watch valley.

New techniques

Dials undergo trends as do cases and straps. The last few years have seen many changes to the world of dials with even the lack of a dial altogether with the popular skeleton watches. One of the most recent advances has been the introduction of the sapphire dial that lets the movement be seen below, but still keeps essential indications for the reading of time and other information. Cadran’or has been developing this expertise over the last five years with new technology that allows painting and engraving on to the crystal itself. Another recent trend has been the three-dimensional dial that has taken away the need for a traditional dial by putting the indications on different levels.

UR103T by Urwerk, HM3 by MB&F

BI-AXIAL by HD3, TOXY 3 TOURBILLON by Romain Jérome

AUTO SKELETON by Armin Strom, HL05 by Hautlence

Take a close look

Next time you look at a watch, take a close look at the dial and try and decipher all the different techniques that have gone into its fabrication. You will be surprised at just how much detail there is. It is so easy to take such things for granted, but the greater our understanding, the greater our appreciation becomes, and for retailers, the greater their ability to share the magic of haute horlogerie with their customers.

The art of restoration

One of the most fascinating places to visit in the watch industry is the dial restoration unit of Stern Creations. Five gentlemen, with over 100 years of collective experience, work exclusively on restoring antique dials that come into the workshop in various states of disrepair. Each dial is restored with as much care and attention as a piece of art. From the indexes to the logo, from the colour of the dial to the circular graining, everything is restored so that no one would ever know that the dial had been damaged. Stern Creations has been making dials for some of Switzerland’s most famous brands since 1898 and the company has amazingly never thrown away a single index or spare logo. Many timepieces have been beautifully restored using original spare parts from the same era of the timepiece – a unique service that is wholeheartedly appreciated by the owners of the watches. To understand the work that is carried out in this magical workshop, pictures speak louder than words, just take a look.

Source: Europa Star October-November 2009 Magazine Issue