Question:

“Recently I bought a sports watch and the salesperson told me that it was equipped with an anti-shock device. What is this device and how does it work?”

Kino Tanaka, Japan

Answer by Professor J.C. Nicolet

Today, it has become nearly unthinkable to sell a sports watch that is not equipped with some sort of anti-shock mechanism, or shock absorber as they are sometimes called. This device is basically a resilient bearing designed to damp the shocks brought to bear on the balance-staff pivots.

A watch is a delicate mechanism composed of many parts, some of which are extremely fragile. For example, the tiny pivots of certain wheels have a diameter of the order of 10 to 12 hundredths of a millimeter (about the size of a strand of hair). The regulator of a watch is a relatively heavy circular wheel whose pivots are among the most delicate parts of the timepiece. If the watch falls onto a hard surface and there is nothing to absorb the shock, the tiny pivots will break. Violent movements made by certain athletes or even card players, if they bang their fists on the table, are enough to break or bend the pivots of the balance-staff, necessitating expensive repairs.

In the 1920s, wristwatches became fairly widespread and with their use, so did the number of “aggressions” the watches were subjected to. Even though less prone to this type of problem, pocket watches also suffered the same sort if dropped.

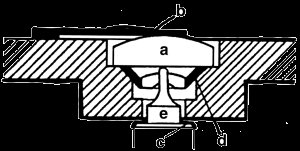

This drawing illustrates the principle of an anti-shock mechanism. The endstone, a, is subject to the action of a spring, b. If an axial shock occurs, the endstone can lift slightly until the shoulder, c, strikes a fixed part of the setting. To damp lateral shocks, the jewel hole is fitted in a setting comprising an inclined plane, d, which provides for a slight lateral shift limited by the collet-arbor or by the roller-arbor, e, which strikes a fixed part of the frame.

A bit of history

As early as the 18th century, the first attempts to protect pocket watches against shocks consisted of placing them in a series of successively larger cases, each having a certain amount of play in relation to the next. This type of protection was used mostly for watches intended for use in Turkey and for those worn by the cavalry and other horsemen (the sportsmen of the era). The watch was placed within two, three or even four larger cases with the first case being rather simple, while the last was often covered with leather. This system of shock protection was without a doubt effective but not very practical. Just to read the hour, one had to spend time opening up several cases.

A little before 1800, Abraham-Louis Breguet, often called the watchmaker of kings and the king of watchmakers, invented a shock-absorbing device called a “pare-chute” intended to protect the pivots of the balance-staff in case of a fall. He replaced the cylindrical part of the pivot by a cone which itself would turn in a ruby cup-bearing mounted in a spring capable of either axial or lateral displacement. In case of a shock, the cup-bearing would move, thus taking the impact of the shock away from the pivots.

Legend has it that Breguet, having a strong sense of publicity, pretended one day to clumsily drop his pocket watch in front of a group of people who looked on in horror. Breguet calmly picked up his faithful timepiece which kept right on ticking, thus winning himself increased admiration from his wealthy clientele. Breguet’s anti-shock mechanism was not within the scope of just any watchmaker of the day and its high price effectively excluded it from being used in most watches. It was only with the introduction and subsequent general use of the wristwatch that interest was regenerated in anti-shock mechanisms. Incabloc and company.

In 1929, the firm Wyler developed a shock absorber with fixed bearings which took advantage of the elasticity of the balance-staff based on a principle of equal resistance. The staff was attached to a balance whose arms in the form of a spiral were themselves elastic.

However, it was in 1933 that an engineer named Hans Marti took out a patent on a system of anti-shock bearings based on a modified version of several of his competitors. In this device, known under the commercial name of “Incabloc”, as in other similar systems, the balance jewel in which the pivot turns, is mounted in a conical setting, which is itself placed in a solid truncated cone in the watch’s frame. The setting also supports the endstone. The entire unit is held in place by a carefully calibrated spring.

When a lateral or axial shock occurs, the setting slides into the cone. This movement permits the pivots to transfer the shock to the frame. The wheels are then pulled back and recentered by the spring which also is removable thus permitting dismantling of the setting and the endstone without having to remove the balance. This is a great advantage for cleaning and oiling. The mass production of anti-shock devices has brought down their prices so that they can be added to watches without an unduly increase in price. In addition to the ease in assembling and disassembling the modern shock-absorbing mechanisms, the oil chamber is protected from dust entry thus ensuring a longer working life of the watch.

Since the invention of the anti-shock device, the balance is no longer the most fragile part of a watch. However, in the case of very violent shocks, other components may break but these in turn are often protected, so that we no longer worry too much about watches being “shocked to death”.