You would think that a watch manufacturer in the middle of China would be a world away from Switzerland. In some ways it certainly is, but at the basic level of making watches, things are not that much different. Parts still have to be made or sourced, movements have to be as-sembled and cased, straps and bracelets have to be put onto the watch and the timepieces have to go into boxes to be transported to clients.

It is not rocket science and the Chinese are starting to get good at it.

Thanks to Genender International and one of their clients NakedWatch, Europa Star got an exclusive tour of a Chinese watch manufacture.

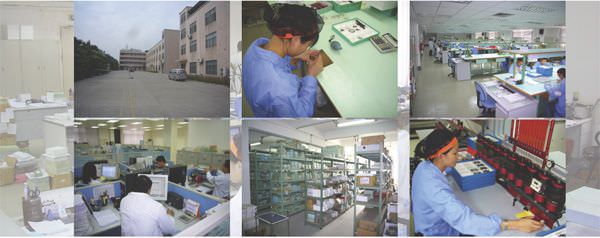

The exterior of the Chinese watch factory, incoming quality control, quartz and mechanical assembly, the design departement of the factory, the storage of all the parts that go into the watches, water resistance testing

Lowest cost migrates

Lowest cost production moves in phases. For watches, lowest cost quartz watch production started in Japan, then moved to Hong Kong (and Taiwan), then to Mainland China. At each step along the way, the workers had to be trained, machines had to be purchased, infrastructure had to be set up and production had to start. Now, even China is on the way out as the lowest cost production, with the future being Thailand, India and Vietnam. As soon as a country has been succeeding, the workers begin to get more skilled and more affluent, labour and other associated costs rise, and the companies have to turn to manufacturing other, more expensive products to survive.

That hasn't completely happened in China yet, but the calligraphy is on the wall.

The factory

The factory that Europa Star visited was outside of Shenzhen, China, in a small, non-descript town called Long Kong. There are many watch factories in the Shenzhen area and, like the Jura Valley in Switzerland, a large number of sup-pliers scattered throughout the region. Because so many companies started in Hong Kong, the nearby Shenzhen area shot up as a viable econ-omical alternative for Hong Kong production.

Other than factories, there isn't much else in the Shenzhen area, and specifically in Long Kong. In fact, the majority of the workers in the plants in this area are brought in from other parts of China, trained by the companies themselves, and all factories have to have on-site dormitories and cafeterias to house and feed their workers.

The dormitories are bleak affairs, with eight to a small room, but the workers who come to Shenzhen are there to work, because the salaries are much higher. In a typical rural village, workers average about 200 RMB a month, while in Shenzhen, the average monthly salary is 1,000 RMB. (Approximately 100¤)

The factory we visited, a joint venture between Genender International and Sonman Industrial Limited, has been in operation for eight years. The factory produces 100,000 watches a month, of which 10 percent are mechanical.

“So many components go into a watch, Shenzhen is the perfect area to make watches,” says Fredi Chan, Owner, Perriland Ltd., a sister company to Sonman. “The factory works five days a week, sometimes with overtime on Saturday and Sunday. The average workday is 9 a.m. to 6 p.m. There is no watchmakers' va-cation here in China. We do shut down for one week over Chinese New Year, when our workers all go home, but other than that, we operate year round.”

The quality in China has been on the rise for a number of years. Genender International, founded in 1937, has been buying watches since its inception.

The tourbillon, a skeletonized and decorated movement for Naked Watch, the cafeteria area of the factory, the prototype and tooling area, readying the product for shipment, watch assembly

“There was a time when the business was all in Switzerland,” remembers Alan Genender, Executive Vice President and Director of International Operations, Genender International. “Then, it shifted to Taiwan, then to Hong Kong, and in the mid to late '80s, people started moving over to China. At first, it was a little shaky doing business in China, quality-wise. Today, the infrastructure is very good. Most of the movements are Chinese - we do business with ETA, Ronda and Japanese movements in our other factories. A lot of the parts and dial manufacturers have moved over to China from Taiwan, even though they still have an office there.”

The tour

Honestly, there wasn't that much difference between the Chinese watch factory and most Swiss factories I have visited. Certainly, Swiss factories are cleaner, better organized and the value of the product on which the workers toil is higher, but other than that, this factory could have been transported to the Jura valley and it would have fitted right in (except for the all Chinese work force, of course).

The chief activity at the Perriland/Genender/ NakedWatch facility is assembly and quality control testing. Like Swiss watch companies, the factory sources movements (ETA mechanical and quartz, Chinese mechanical and quartz), parts, cases, straps and bands and assembles them all in the factory.

The workers number about 260, down from 350 last year. According to Chan, it's tough to keep qualified workers, as they are there for the money - as soon as another company offers more, the workers are gone.

Sound familiar?

The tour featured all the aspects I have come to expect when touring a Swiss factory - design, purchasing, incoming quality control, assembly and production, water resistance, testing, strap assembly, final quality control, shipping and more. It was an impressive facility, very suited to high volume quartz production. Now, a small percentage of the factory's production is mechanical, including three hand watches, annual calendars and even a tourbillon.

TOURBILLON, MALCOMB and MAXWELL by NakedWatch

Mechanical movements

Genender International has been buying Chinese mechanical movements since the 1970s and, with diligence and attention to quality control, Genender believes it's possible to produce quality mechanical watches with Chinese movements.

“For what we are doing with NakedWatch, we predominantly use Seagull (located in Shanghai), especially for the tourbillons,” Alan Genender says. “The quality of the movements has been amazingly stable. The Chinese have been making mechanical movements for a very long time. When the rest of the world was going quartz, the Chinese stayed mechanical because the people didn't trust batteries in their watches. They maintained the mechanical business throughout China. Seagull is the strongest and the best quality, but there are three or four other major manufacturers.”

NakedWatch was established six years ago, with the express desire of providing customers with quality skeleton mechanical watches at reasonable prices. “We feel we are making an affordable, quality, clean timepiece,” says Doug Flentge, Vice President of Sales and Marketing, NakedWatch. “We really don't like batteries - we live in the mountains here in Colorado and we like to take care of the environment. We are really in love with the manual wind and the automatic, and we are trying to emphasize the movement, which is why we only do skeletons. I like the bold, clean style. For us, it's the whole package.”

The price range for NakedWatch products is US$200 - US$479, with the new tourbillon going up from there, though no price has been set yet. “It's a hand made tourbillon that can be customized,” explains Flentge. “We want to provide people with a real tourbillon that is custom made to their taste, in either a gold plated or solid rose or yellow gold case. We can't find a real, customized, skeleton tourbillon for under US$100,000, and we can offer customization at a tenth of that price.”

NakedWatch, which in 2007 made and sold 3,000 watches, is doing quite well. The majority of their sales are direct off their website, but they are starting to work with retailers in the United States and other parts of the world.

“People have come to us and that's how we have gotten our retail presence,” Flentge says. “It's not the Chinese movement that has given us the biggest trouble; it's the fact that people don't know NakedWatch. We have built up a good following in the watch industry. In the mainstream, NakedWatch is relatively unknown. The brand is very enticing - we have had great conversations with top retailers to go into their stores in 2008.”

“The future for NakedWatch is wide open, the sky is the limit for what we can do,” he continues. Our vision is to always provide a skeleton movement at an affordable price. That will not always mean Chinese movements. We will have Swiss movements in the future. We hope to have a chronograph out later this year."

The future

The Swiss don't have to worry about the Chinese just yet.

“I think it's going to be tough for Chinese movements to be a direct competitor to the Swiss,” Genender says. “The Chinese lack savvy marketing. The Swiss are amazing marketers of their incredible products. The entire world, when they hear Swiss, think quality. The Chinese aren't sophisticated enough from the marketing aspect. They can copy, they can produce, but they don't know what to do with it once it's made. Secondly, in Switzerland, there is a lot more use of precious metals, but in China, you don’t have that. Most factories are scared to deal with precious metals - if they have it in their factory, they think someone is going to steal it.”

Chinese movements are penetrating the market at large. For example, Fossil recently purchased 800,000 mechanical movements from Seagull for their products. No one thinks that the Chinese will supplant the Swiss anytime soon, but the Chinese mechanical movement is clearly here to stay.

And that's not a bad thing.

If someone buys a mechanical watch at an opening price point of US$200, and falls in love with mechanicals, as many people do, it's only a matter of time before that person steps up to a higher priced mechanical...and another watch lover is born.

Source: Europa Star February-March 2008 Magazine Issue