fter several years of planning, Swiss company mb-microtec, a leader in the manufacture and production of self-illuminating gaseous light sources, announces that it is gradually putting into operation a recycling plant for tritium gas that is the only one of its kind in all the world. The specially developed system enables the safe and sustainable degradation of the rare isotope tritium.

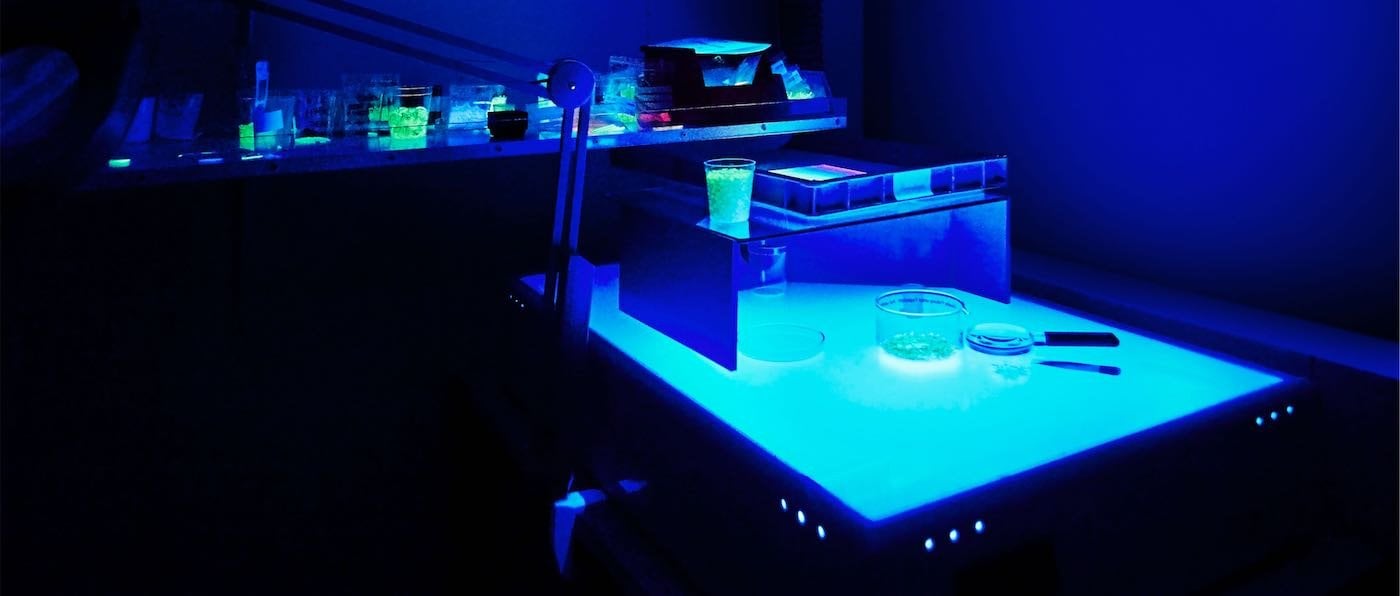

The microtechnology company is the inventor of the unique self-powered illumination technology called trigalight and is a global leader in its development and manufacture. The glass capillaries are coated with a luminescent powder (zinc sulphide) and made to glow with the use of tritium.

Their light output lasts for decades without an external energy source. trigalight is used in the security and automotive industries, in the aerospace industry and in the watch-making sector. With its own brand of watches, traser swiss H3 watches, mb-microtec has launched the world’s first self-powered illuminating watch.

As with almost every production process, waste is generated in the manufacture of trigalight. This takes, for example, the form of leftover pieces from the manufacturing process. Since these contain low-level radioactive tritium, this waste was previously welded into gas-tight cylinders and temporarily stored. The question of how these can be sustainably recycled has long been an issue at the Bern-based company.

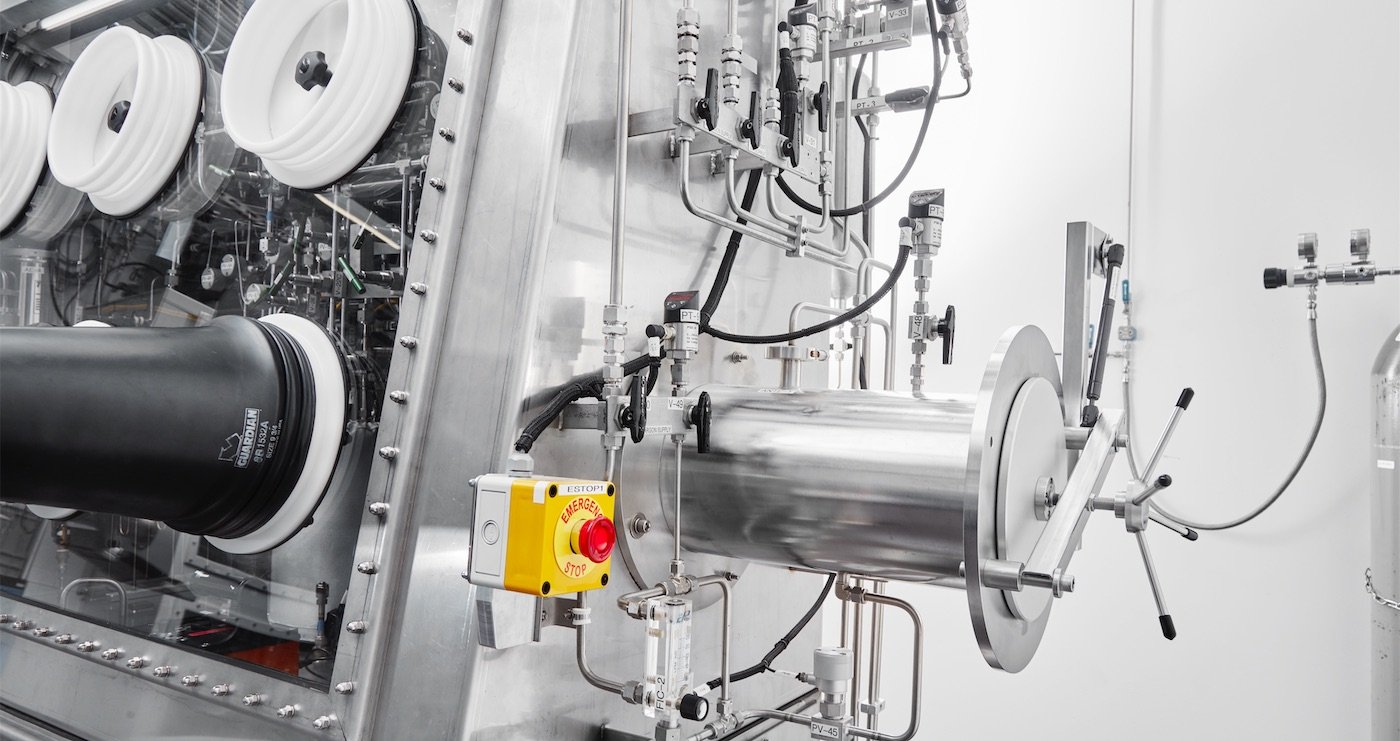

Now, however, their commitment to sustainability is really gaining momentum: after intensive planning, the unique recycling facility for tritium, which has been in Niederwangen since last year, will be put into operation in stages, under consideration of the official requirements. At the same time, the system is constantly being adapted and optimized.

In principle, it works similarly to wastewater treatment: the tritium is extracted from the trigalight, released through a filter and can be reused in its entirety. The quality of the recycled gas is identical to the quality of any newly purchased tritium. Although relatively large amounts of tritium can be processed, emissions are comparatively low. For mb-microtec, this was and still remains one of the most important prerequisites for commissioning the highly automated system in the first place.

This is a revolution for the watch industry: traser swiss H3 watches will be the first brand to offer sustainably produced self-powered illuminating watches. In a second step, in addition to recycling the production waste, it will also be possible to dispose of and recycle sold products.

With the commissioning of the world’s only active tritium recycling facility, mb-microtec is taking another big step towards sustainability and innovation – and it is exactly because of these factors that mb-microtec made it onto the list of six nominees for the Prix SVC from over 240 companies. The award will be presented on 19 August 2021 in the Kursaal in Bern. For the company, this nomination is confirmation that it is on the right track.