A true stylistic and very Italian culture exists at Bulgari, one that is expressed in all of the brand’s product ranges, whether jewellery, accessories, or even hotels. Its watches are no exception. But this so very particular style – a very Italian design whose exuberance remains however measured by a demand for elegance – when it comes to watches involves some serious technical requirements. With their combinations of harmonious forms and very striking volumes, rounded curves and pronounced lines, aluminium and rubber, Bulgari timepieces nonetheless are technically advanced, and often very complex in their construction.

With a desire to totally distance itself from the ‘fashion’ watch sector, Bulgari has gradually been led to merge its own Italian culture with another culture, that of Swiss watchmaking. Brick by brick, Bulgari has vertically constructed its own timekeeping edifice. Its goal has been to not only progressively ensure its own independence in terms of production, but also to better understand and gradually integrate into its own operations the savoir-faire of Swiss watchmaking.

The Bulgari watch pole

Today, Bulgari’s watch department has become a veritable group, and is in the midst of becoming totally integrated. It is composed of four specialized and complementary companies: Bulgari Time, Gérald Genta and Daniel Roth, Prestige d'Or and Cadran Design.

The decision was made to not house these various companies under one roof, so that each can continue to work ‘in their own biotope’ (Neuchâtel, Jurassian Arc, and the Vallée de Joux), as well as to continue to have real ‘entrepreneurs’ at their helm.

![]() Bulgari Time, based in Neuchâtel, is the real hub of the dispersed ‘manufacture.’ It is here that product strategies are elaborated, marketing plans are created, and ‘briefs’ are established – products based on design propositions coming directly from Bulgari’s design teams located in Rome. Bulgari Time is also the centre for quality control and technical testing as well as for assembly of all watches bearing the Bulgari label (with the exception, as indicated below, of the complications created by a unit based at Gérald Genta and Daniel Roth).

Bulgari Time, based in Neuchâtel, is the real hub of the dispersed ‘manufacture.’ It is here that product strategies are elaborated, marketing plans are created, and ‘briefs’ are established – products based on design propositions coming directly from Bulgari’s design teams located in Rome. Bulgari Time is also the centre for quality control and technical testing as well as for assembly of all watches bearing the Bulgari label (with the exception, as indicated below, of the complications created by a unit based at Gérald Genta and Daniel Roth).

![]() Gérald Genta and Daniel Roth, located in the heart of the Vallée de Joux, is the developmental centre of all the complicated watches in the Bulgari group. It is also the group’s pole of timekeeping excellence. Acquired in 2000, restructured, and today in a growth phase, this company is responsible for developing Bulgari’s first in-house calibres, in addition to the activities of the two brands themselves.

Gérald Genta and Daniel Roth, located in the heart of the Vallée de Joux, is the developmental centre of all the complicated watches in the Bulgari group. It is also the group’s pole of timekeeping excellence. Acquired in 2000, restructured, and today in a growth phase, this company is responsible for developing Bulgari’s first in-house calibres, in addition to the activities of the two brands themselves.

![]() Prestige d'Or, in Saignelégier, is a firm specializing in the development and production of gold and steel bracelets. The company also makes all the component parts for these bracelets.

Prestige d'Or, in Saignelégier, is a firm specializing in the development and production of gold and steel bracelets. The company also makes all the component parts for these bracelets.

![]() Cadran Design, in La Chaux-de-Fonds, is an expert company in creating complicated dials. Its production, devoted exclusively to special dials, runs the gamut from the single unique dial to a series of 150 pieces.

Cadran Design, in La Chaux-de-Fonds, is an expert company in creating complicated dials. Its production, devoted exclusively to special dials, runs the gamut from the single unique dial to a series of 150 pieces.

For the production of its cases, Bulgari has chosen not to integrate this activity into its ‘manufacture’ but rather to work in close partnership – based on a centralized computer system controlled by Bulgari Time – with a series of external suppliers.

A visit to Bulgari Time

Bulgari Time, installed in a handsome building in Neuchâtel, is the nerve centre of this constellation of companies. One of its main duties, insist its managers, is the ‘Quality Concept’ that covers all the watch activity of the group. This quality assurance, directed from Bulgari Time, ‘is a constant reflection, a permanent concern,” says one of the managers.

Let’s begin with the marketing office. Composed of 11 people, divided into three units corresponding to different product lines (Classic, Sport, etc.), it is responsible for the launch strategy of the various products whose development is projected over five years. This department is also in charge of assuring the Quality Concept throughout the entire length of the development chain. The level of integration between marketing and operations is very high, in order to encourage mutual understanding of the difficulties or demands in each department. Moreover, the marketing department is responsible for calculating the margins and the price level of the products, as well as the training of sales personnel.

The technical bureau, made up of seven people including four constructors, ensures the transition between the design coming from Rome and the feasibility of making the piece. It thus translates and creates models of the preliminary drawings from the Rome designers, transforms them and works to integrate the movement.

From there, the project passes to the Methods Office, where six people work to bring the developed products to an industrial scale: project monitoring, homologations (and notably a battery of tests for nickel, leather, solvents, etc.), codification of the component parts from diverse sources, detailed assembly procedures, development of tools for assembly and after-sales service, and elaborating the procedures to follow for protecting the watches during delivery.

The Office for Technical Control checks all of the component parts when they arrive from the various suppliers and then it checks all the finished pieces. It is divided into specialized control units: cases, straps, dials, movements, etc.

While the industrial pre-series pieces are all checked, the full production line series are only spot checked, except for water-resistance, where every watch is tested, as well as watches equipped with automatic movements. Using advanced equipment, this control unit has developed its own procedures, for example, in checking water resistance, where it uses a very unique machine that allows the testing of the activating and de-activating of the pushbuttons of the Scuba SC 40 chronograph directly under the water!

Finally, the assembly ateliers of Bulgari Time deal with nearly all of the brand’s watch products. Working in the traditional manner, where work is divided, the various units are alternately responsible for placing the dials and hands into a pre-assembled case, then lastly attaching the strap. Specific products are handled by specialized watchmakers (most movements come from Piguet and ETA). The work is all done by hand.

The watchmaking competencies of Genta and Roth

One of the objectives of Bulgari’s current verticalization is to gradually reach autonomy, partial or not, in terms of the movement. Since its acquisition of Gérald Genta and Daniel Roth, Bulgari has adopted a policy of moving upmarket in the watch sector, which leads it today to propose complicated timepieces, a move that will continue. At Genta and Roth, a team is devoted specifically to the gradual development of movements that are purely Bulgari, and to mechanisms that are specifically reserved to the brand. In time, Bulgari intends to develop its own mechanical base. This is a long-term effort that will include growing sophistication in complications that the brand is already offering and will offer in the future.

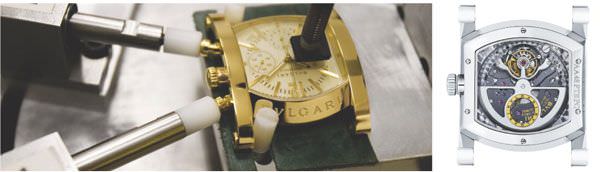

Take, for example, the Assioma Multi-Complication Skeleton timepiece presented this year at BaselWorld (a perpetual calendar tourbillon with a second time zone). The movement was created by Genta but was entirely reworked for Bulgari. The gold mono-block oscillating weight, cut out with an incrusted ring logo and lacquered on the top side, was completely redone; a new gearing system was developed; the pushbutton was transformed; rhodium-plating was added, etc. All this gives the piece a striking transparency, with an ultra-contemporary face – in the Bulgarissime style, of course.

ASSIOMA MULTI COMPLICATION SQUELETTE, ASSIOMA PETITE COMPLICATION, DIAGONO TITANIUM

Cultural changes

This new approach to timekeeping (we also see it in the series of the Assioma Petite Complication, using a GP calibre, with its black coating and ‘rough’ satin finishing) is “a genuine cultural change, not only for Bulgari, itself, but for the brand’s traditional clients,” say the brand’s managers. It is an entry into a new market, with pieces whose finishing is carried out in the great traditional art of haute horlogerie, but with a modern touch unique to the brand from Rome.

This effort is particularly visible in the Decoration Atelier that was recently inaugurated. Circular-graining, spiral finishing, Côtes de Genève, hand chamfering… While the techniques are traditional, they have been ‘diverted’ in an effort to accommodate Bulgari’s dual culture: Italian in its expression, high watchmaking in its execution.

Thanks to high performance equipment (the facility is able to realize all the tooling and manufacture of the necessary component parts), the global competence of the Genta and Roth manufacture, and its expertise in timekeeping, Bulgari can henceforth envision a real rise in power in the domain of mechanical haute horlogerie. Strategically, this opening is fundamental. It will allow the brand to not only establish a true watchmaking legitimacy in the haut de gamme sector, thus gradually ensuring its mechanical autonomy, but it will also and above all, allow it to reposition itself among the great actors on the stage of timekeeping. A real cultural revolution.

Source: Europa Star August-September 2007 Magazine Issue