By placing its exceptional trilogy of grand complications under the sign of Hybris, Jaeger-LeCoultre has caught everyone by surprise. As we know, for the ancient Greeks, ‘hubris’ meant immoderation and excess—pushing the limits—contrary to moderation and temperance.

And isn’t the current crisis precisely the result of ‘hubris’ that has possessed the players in the global economy? But in hubris, there is also the notion of challenge. Wasn’t Prometheus, who brought fire, and thus civilization, to mankind, also acting while possessed by his own hubris? Isn't it also the challenge that leads to progress?

Whatever the case, the exceptional trilogy of grand complications presented this autumn by Jaeger-LeCoultre—the Hybris Mechanica 55—epitomizes a truly remarkable challenge. It also clearly demonstrates that the manufacture in the VallÉe de Joux intends to position itself at the very summit of watchmaking hierarchy.

In order to discover this trilogy, however, you will first need the code to open the biggest and heaviest presentation box in the history of timekeeping.

Weighing in at just over one ton and measuring 1.5 metres in height and 1 metre in width, this box is an authentic, luxurious and ultra-secure leather-coated steel safe sporting the colours of the brand.

What you notice first about this safe is the delicate sound of a Westminster carillon chiming the hours and quarter-hours that is mysteriously emitted from within. Behind this mystery is an ingenious acoustical system, with no microphone, speakers or wires, which faithfully transmits the chime coming from one of the brand’s ‘immoderate’ watches—the Hybris Mechanica À Grande Sonnerie.

ULTRA-SECURE LEATHER-COATED STEEL SAFE

The trilogy of immoderation

Upon opening the safe’s door, you discover the Hybris Mechanica à Grande Sonnerie, which is in the company of two other Hybris timekeepers—the Hybris Mechanica à Gyrotourbillon and the Hybris Mechanica à Triptyque. They make up a prestigious trio that, like its generic name indicates, comprises a total of 55 watch complications. The Gyrotourbillon and the Reverso à Triptyque need no introduction.

The first is a superlative tourbillon, presented by Jaeger-LeCoultre in 2004, which can rightfully be called the first true tourbillon for a wristwatch thanks to its spherical carriage that rotates around itself as well as around a secondary axis (since we have known for a long time that the ‘normal’ tourbillon only really compensates for the effects of gravity in the vertical position, as in the case of a pocket watch carried vertically in a vest pocket). This fascinating timepiece features ten functions: hours; minutes; seconds on the tourbillon; perpetual calendar with date and month by double retrograde hands; leap year indicated on the back; equation of time and an eight-day power reserve. In its Hybris Mechanica version, in white gold rather than platinum, the dial of the Gyrotourbillon has been skeletonized in order to fully showcase the complexity of the movement.

Introduced in 2006, the Reverso à Triptyque is the only watch in the world to have three dials with 19 complications. The first displays civil time. The second shows sidereal time with a zodiac calendar, star chart, equation of time and the times of sunrise and sunset. The third contains a perpetual calendar with jumping date, retrograde date and phases of the moon. In its Hybris Mechanica version, the tourbillon of this white gold Reverso à Triptyque features a new ellipse isometer escapement with a very special platinum-iridium balance that was created for the Master Compressor Extreme Lab.

HYBRIS MECHANICA TRIPTYQUE, HYBRIS GYROTOURBILLON

HYBRIS MECHANICA A GRANDE SONNERIE

The crowning achievement

Even more extraordinary than these two amazing timekeepers is the Hybris Mechanica à Grande Sonnerie, a masterpiece that alone comprises 26 complications. In today’s world, it is indeed rare for a brand or independent master watchmaker to even attempt this crowning achievement in the art of timekeeping—the grande sonnerie, plus a repeater. We can count these rare accomplishments almost on one hand: Patek Philippe, Gérald Genta and Daniel Roth, François-Paul Journe, Philippe Dufour, Audemars Piguet...

Over the course of its 176-year history, Jaeger-LeCoultre has designed and produced nearly 1,000 different calibres. Among them are some 200 repeater calibres, musical watches or alarm pieces. Between 1866 and 1903, the manufacture produced 99 different calibres equipped with repeater mechanisms or grande sonneries. One of these, for example, made around 1892, was a grand complication pocket watch featuring a minute repeater with a silencer on the gear train, chronograph, perpetual calendar, leap years and phases of the moon. At the beginning of the 20th century, extra-flat minute repeater pocket watches marked the history of timepieces, as is exemplified in the complicated, minute repeater pocket watch dating to 1920 whose movement was barely 3.2 mm in thickness—a true technical feat for the era.

Later in the century, beginning in the 1950s, Jaeger-LeCoultre explored other functions related to sound, notably in its Memovox, which literally means ‘voice of the memory’, a famous alarm watch that has today become a collector’s item. These examples all show that mastering musical watches has been an important element of the manufacture’s activities. Yet never before has Jaeger-LeCoultre created a grande sonnerie for a wristwatch.

Starting with a blank slate

This absence of a grande sonnerie in a wristwatch thus represented an opportunity, according to David Candaux, the brand’s watch constructor who set about designing this new movement. He adds that everything began with a blank slate, and that the specifications for this new device were extreme: the grande sonnerie had to fit in a case from the DuomÈtre line of watches, meaning a maximum diameter of 44 mm and a thickness of 15 mm.

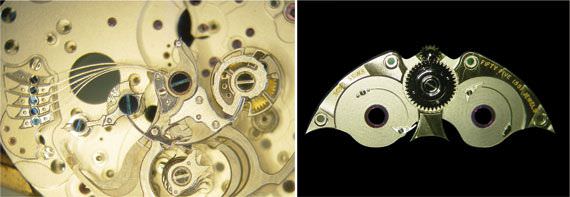

Step by step, the brand’s construction unit tackled the problem. Development took five years, and included many innovations along the way in order to fit more than 1,300 component parts into this small space. The development phase also resulted in not less than 13 patents. Working on a 37 mm plate, the constructor first placed the two barrels (one for the time and the other for the striking mechanism) side by side, as in Jaeger-LeCoultre’s Dual Wing system, which lets one barrel be wound in one direction and the other in the other direction with the same crown.

Candaux then placed a flying tourbillon in close proximity with a titanium carriage and a 10 mm balance wheel. Mounted on a ceramic ball bearing, the tourbillon has no bridge on its upper side and only one arm. In order to save space, the arming system is equipped with a conical pinion while two spherical differentials replace the two usual planetary wheels. From there, a first gear train goes to a centrifugal governor fitted with a flywheel to silently control and distribute the energy released by the striking barrel.

The striking mechanism, the positioning of the two barrels

The flying tourbillon, view of the four pushers on the side of the case

Hammer concerns

The choice of the melody went to the classic and very watch-oriented Westminster carillon (a melody composed by Haendel), otherwise known as the Big Ben chime.

In the case of the Hybris Mechanica à Grande Sonnerie the 4th quarter chimes play an ad-ditional 8 notes and a total of 24 notes on the passing hour. This increases the complexity of the watch and has made the Hybris Mechanica à Grande Sonnerie’s chimes the longest ever with a total of 36 notes at 12 o’clock.

With the rack in place followed by the hammers, there were problems of energy and space. In the case of a traditional hammer striking the gong, about 80 percent of the energy furnished by the rack is lost into the mass of the hammer itself. Also, although not visible to the naked eye but observable on a film taken at 1,000 images per second, the traditional hammer poses a serious problem of adjustment since, after its strike, it rebounds several times on the gong before coming to a stable position just above it. These rebounds alter the quality and purity of the sound.

The solution found by the Jaeger-LeCoultre team is totally original, and of course patented. The brand’s watchmakers invented a device called the ‘Trébuchet Hammer’ (named after the counterweight catapults invented in the Middle Ages), which is made up of two moveable parts held together by a spring. During the strike, the moveable front part of the hammer, acting like a lever, strikes the gong precisely and firmly one time and then moves back quickly. This mechanism helps the sound quality that is emitted in this small space.

The four hammers and the striking mechanism on the face of the watch and from the back.

The ‘Infernal Tower’

The grand sonnerie repeater, however, poses another problem—that of the sequence of the chimes depending on the different modes chosen, which chime in passing or repeated mode. In the ‘in passing’ mode of the grande sonnerie, the quarter-hours are chimed first, followed by the hours. But in a traditional minute repeater, it is just the opposite—the hours are chimed first, followed by the quarter-hours and then the minutes. There is also another problem. In the repeater mode when there is no quarter-hour but only minutes (for example at 12:07), a traditional repeater would chime the hours then remain silent for the quarter-hours before striking the minutes. The Jaeger-LeCoultre watchmakers insisted, though, that they wanted to eliminate this lapse of silent time so that the minute would directly follow the hour.

Solving this double problem in order to arrive at a perfect grande sonnerie and minute repeater, at all costs, was not an easy task. Finding the answer led the constructors to invent new mechanical solutions contained in what David Candaux playfully calls the ‘Infernal Tower’.

Trying to describe this central mechanism that drives the chimes (and the time display as we will see below), and reverses the order of the chimes depending on the mode selected, is also no easy task. In a few words, the infernal tower is a system of backwards and forwards motion composed of tiered levels of cams and snails on the same axis and incremented by the seconds wheel. The minute snail is at the bottom of this tower. Above it is the hour snail, which naturally makes one rotation in an hour, and the four quarter-hour cams, each of which makes a rotation in two hours, driving the tiered return springs next to them, which are staged in a very architectural manner.

The infernal tower, acting as the ‘brain’ of the watch, is driven by a second column whose function is to deliver the various speeds. This drive system is completed by a special device called a ‘conjuror’ that allows the system to pass directly from the hour chime to the minute chime by mechanically ‘skipping’ the quarter-hour cams.

–Visual and sound synchronization

This infernal tower, the central nervous system of the watch incremented by the seconds wheel, distributes the time for both the displayed time and the chime in a perfectly coordinated way. This is an elegant and innovative manner to avoid what often happens in watches with chimes, which is a loss of synchronization between the visual time reading and the strike of the chime. Logically then, this centralized system generates jumping (digital) hours and minutes. Another concern of the designers was to be able to set the time without damaging the chime mechanism when the watch is in the sonnerie mode—a major problem for most repeater watches.

Their solution was to find a different way to set the time, which meant not using the crown, which is used only for winding. The designers created one pushbutton for setting the hours and two other pushers for setting the minutes upward or forward. The minutes can thus be corrected in either direction. Upon quitting the silent mode (activated by a fourth pushbutton that engages automatically after six hours of the watch’s operation in order to save energy) or activating the repeater using a pushbutton integrated into the crown, a clutch mechanism integrated into the gear train immediately disconnects the time-setting pushbuttons, thus preventing any inadvertent or dangerous manipulation. This makes correcting and setting the time as simple and harmless as child’s play.

Science and sensibility

A grande sonnerie would be nothing without high quality sound. In this regard, Jaeger-LeCoultre has taken the lead with its studies, beginning in 2005, conducted on the development of the Calibre 947 with its patented crystal gong. The gong’s support is soldered to the watch’s sapphire crystal since sound transmission is enhanced through the crystal, thus increasing the intensity and purity of the sound vibrations.

This gong in the grande sonnerie is made from a single block of an alloy whose composition remains secret. It is not completely round but comprises a straight section on which the hammer strikes. The cross-section of the gong is square, narrow at its attachment point and gradually widens towards its other end. This special geometry results from studies on sound quality, purity and intensity conducted using science and sensibility.

The intensity, sustainability and richness of the sound are closely related. Research to find the best compromise possible between the sound’s intensity and sustainability, and research relative to the differences between the hours, quarter-hours and minutes, is carried out by systematic analyses using the ‘ear’, which remains indispensable, and with specially developed acous-tical equipment that includes ultra-sensitive microphones to pick up, analyze and transmit the sound’s data in a digital form.

This gong is directly attached to the watch’s sapphire crystal so that the bezel and case, in white gold and chosen for its acoustic qualities, help enhance the sound. Nonetheless, the case remains water-resistant. For the minute repeater of its Hybris Mechanica à Grande Sonnerie, Jaeger-LeCoultre chose to strike the hours on a low-pitched gong, the quarter-hours with the according Big Ben melody on the four gongs and the minutes on a high-pitched gong.

Mastered excess

Six watchmakers from Jaeger-LeCoultre’s Atelier des Spécialités Horlogères are each in charge of the total assembly of each watch. It is a thorough assembly—dismantling, cleaning, reassembly, adjustment, testing, placing of hands, encasing—a process that takes more than a month, without even counting the 1,000 hours of tests that each Jaeger-LeCoultre watch must undergo. Just a temporal drop in the ocean for this amazing timepiece.

We must not forget, however, that in addition to the carillon, whose melody is the longest in watchmaking history, the Hybris Mechanica à Grande Sonnerie is also equipped with a perpetual and instant calendar, retrograde day, month, and date, leap year display, as well as a power reserve indicator for the sonnerie and another for the watch. Does this lean toward ‘immoderation’? Yes, but this immoderation has been mastered with consummate skill. It truly allies the essence of the art of traditional timekeeping (the grande sonnerie is one of the oldest complications) with dazzling modernity.

Source: Europa Star August-September 2009 Magazine Issue