Not less than nine inaugurations of new manufactures or the official laying of foundation stones were held during the month of September, all in a very small area, between the Vallée de Joux, the Val de Travers, Neuchâtel and Bienne. In the middle of the watchmaking crisis, this is an encouraging sign for the future, even though, of course, a manufacture is not built in a day. It involves heavy investment both in financial and human terms, based on decisions made much earlier (when things were better), an investment for the long term. Targeting the long term means that those companies equipped with the necess-ary tools can rebound better than the others when the recovery comes. In addition, these inaugurations constitute further confirmation of their ‘independence’, regardless of the ‘surface area’ of these companies, which range from the historic manufacture of Audemars Piguet in Le Brassus, to the more recent ones such as Fleurier Ebauches attached to Chopard and Vaucher, which is attached to Parmigiani, both located in Fleurier in the Val de Travers. We might also mention the more modest, but very impressive new manufacture, Armin Strom, located in Bienne as well as the new ateliers constructed in La Chaux-de-Fonds by Greubel Forsey and Vincent BÉrard without forgetting the extension of the Ulysse Nardin manufacture, or the official laying of the first stone of the new Rolex manufacture in Bienne and the beginning of construction of the Jaquet Droz facility in Crêt-du-Locle. The following is a brief tour of the landscape.

The small jewel of Armin Strom

We begin with the major investment in the more modest company, Armin Strom. Four years ago, this specialist in the creation of skeleton movements became associated with a family of industrialists (the Michel family is the main shareholder) with the objective of giving new impetus to the brand including the means to develop and produce its own movements. The relatively modest facility, designed like a much larger one, was recently inaugurated in Bienne where it employs 16 people.

Inside this completely restored building with large open and airy spaces, Armin Strom can now claim to produce, in-house, almost all of the components used in its own movement (with the exception of the regulating organs, which are furnished by Engineering in Schaffhouse, attached to H. Moser & Cie). Gears, screws, pinions, plates, bridges etc., are all manufactured by Armin Strom using brand new equipment (milling, electro-erosion, cutting, three-axes tooling centre etc.).

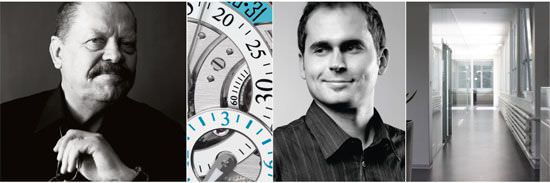

Armin Strom and Serge Michel

Begun only in 2008, we are surprised at the relative short period of time needed to complete this project. Serge Michel, Director of the brand, smiles. “Thanks to the crisis, not only were the machines delivered to us quickly, but we immediately found very qualified personnel that allowed us to begin right away. The economic slowdown had a paradoxically good side for us. It did not push us to move faster than necessary, thus giving us the time to optimize our quality. When the recovery happens, we will be ready.”

Besides the fabrication of component parts, the small manufacture also has an atelier for electroplating and for decoration, thus providing it with the means to master all the very elaborate finishings of its pieces in-house. The assembly and encasing are also carried out in the Bienne facility. “For me, who began forty years ago, this is an immense satisfaction,” says Armin Strom happily. “I am very proud of this tool, managed by young and enthusiastic people. I want to take advantage of it to develop something that I hold especially dear—the transmission of my knowledge. Apprentices will always be welcome here.” We can discover the brand’s new movement in November when the essential components will be revealed, then at BaselWorld for the finished products.

Planning for the future: Part 2

Planning for the future: Part 3

Planning for the future: Part 4

Planning for the future: Part 5

Source: Europa Star October-November 2009 Magazine Issue