he starting point was a simple observation: Switzerland imports 140,000 tonnes of steel per year; the watch industry consumes 15,000 of those, and its steel waste travels up to 42,000 kilometres before being recycled — only to be shipped back to Switzerland.

“An ecological as well as an economic aberration,” says Raphaël Broye, the passionate CEO of Panatere, who set out to recover valuable steel swarf locally and melt it on site using the power of the sun, further reducing the process’s energy footprint.

-

- Raphaël Broye, CEO of Panatere

The dream becomes reality

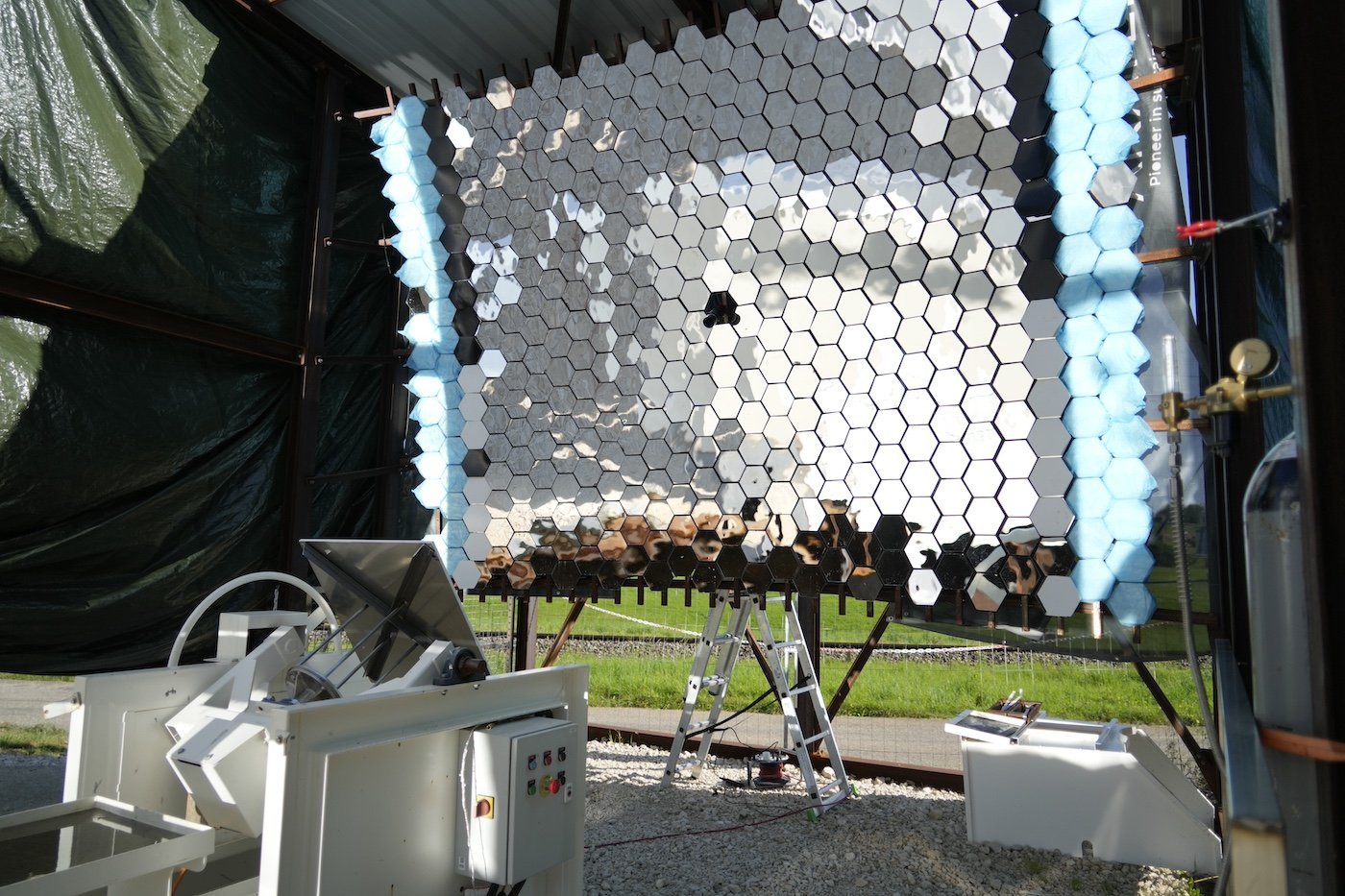

Thanks to the hard work of nearly 150 people over ten years, the dream has now become reality. Switzerland’s first two solar furnaces were inaugurated on Friday, 3 October, in La Chaux-de-Fonds.

Raphaël Broye experienced the moment with the emotion characteristic of true pioneers: “This is a historic day — the culmination of ten years of dreaming, persistence, and patience that proves we can add value to our waste and give it a new, clean, and sustainable life. It’s also proof that an energy transition reducing environmental impact and dependence on fossil fuels is possible.”

As a symbol of this determination and sense of responsibility, the first solar steel ingot smelted in Switzerland — on 6 March 2025 at 13:24 — is now on display at the Musée International d’Horlogerie in La Chaux-de-Fonds.

Circular economy: a paradigm shift

The inauguration of these two furnaces was made possible not only by the vision and tenacity of the teams but also by strong collaboration between private companies, research organisations, and both local and international public bodies. The Swiss Confederation, the cantons of Neuchâtel and Jura, the European Interreg committee, the Bourgogne–Franche-Comté region, EPFL, CNRS, CEM, the Swiss Climate Foundation, the Federal Office for the Environment — and many others — all contributed to the CHF 15 million required to bring these pioneering furnaces to life.

As Ilinka Guyot, Municipal Councillor of La Chaux-de-Fonds, noted at the inauguration: “This inauguration writes a new page in Swiss industrial history and shows how our models must reinvent themselves to make economy, ecology, and equity coexist.”

Laurent Favre, State Councillor of the Canton of Neuchâtel, added: “This innovation demonstrates that we can build more resilient ecosystems that reduce dependence on distant suppliers as well as ecological impact. This is a major strategic issue in a world where access to raw materials is increasingly strained.”

Reducing steel’s environmental impact by a factor of 165 — from 6.8 kg/tonne for traditional smelting to just 0.041 kg/t for solar steel — is both responsible and deeply meaningful.

-

- Inauguration of Panatere’s solar furnaces

First step

And this is only the first step. The stated goal is to build, by 2028, a large solar metal-processing centre capable of producing 1,000 tonnes of recycled solar steel. The concentrator will measure 35 metres per side (compared with today’s 10-metre diameter), while the heliostat — an array of mirrors reflecting the sun’s rays towards the concentrator — will extend over no less than 200 metres.

Building permit applications have already been filed for a site in La Chaux-de-Fonds or Sierre. The investment, estimated at CHF 65 million, will once again rely on the support of all responsible stakeholders.¨

Will we then see the birth of a label for Circular (and Solar?) Swiss Made steel? Perhaps. But as Raphaël Broye and his team have shown — dreaming big is where progress begins.